ECO Forest Engineered Bamboo Flooring

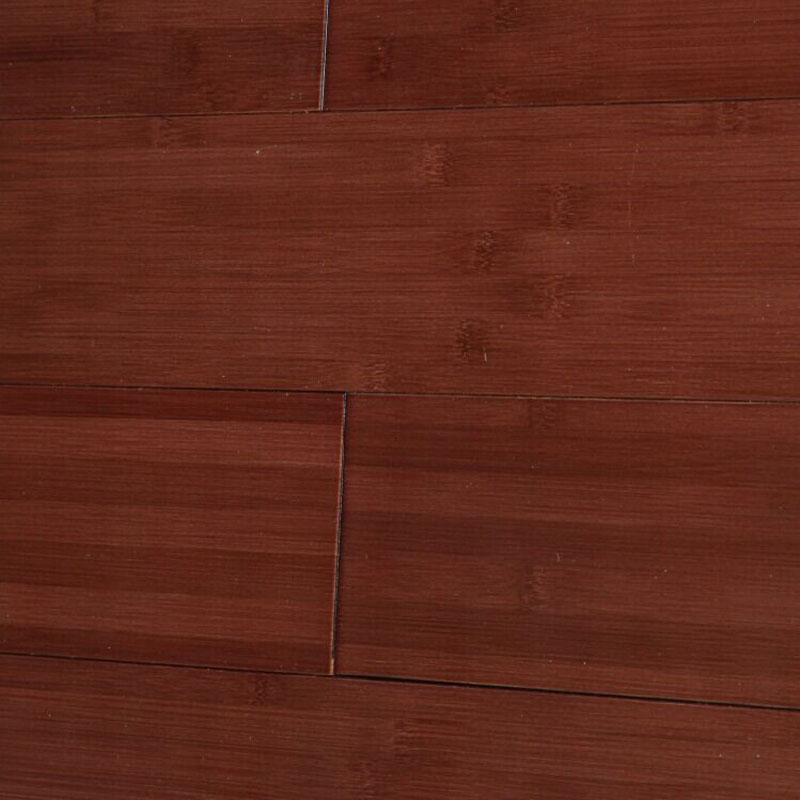

Carbonized Bamboo Flooring

Natural Bamboo Flooring

Strand Woven Bamboo Flooring

How To Choose Floating Bamboo Flooring?

Choose Best Floating Bamboo Flooring for your home , you need know how select.

Below is some Professional advice

1. First look at the face:

There are no bubbles in the paint, whether it is fresh and bright, whether the bamboo joints are too dark, and whether there are glue lines on the surface (one by one uniform and straight line, the machining process is not fine, the heat pressure is not caused by other reasons) and then check whether there are cracks around , Whether there are any traces of ash. Whether it is clean and tidy, and then see if there is any remaining bamboo on the back, and whether it is clean and tidy. After reading everything, we need to inspect the goods to see if there is any difference between the sample and the actual product. The last item is installation. If the keel needs to be punched, it is about 30 cm in accordance with the standard. The standard plate needs four keels.

2. Check the inner material of bamboo flooring

Check the material, first observe the cross section at both ends of the floor. If the structure is symmetrical and balanced, the floor can ensure stability. Then break the floor with your hands to see if it is easy to delamination, and check whether the floor layer and the interlayer glue are tightly bonded.

3. Look at environmental protection:

For laminate flooring, the most important criterion for floor environmental protection is the amount of formaldehyde released. Regarding the limitation of formaldehyde emission standards, environmental protection in the floor industry has experienced three technological revolutions of E1, E0, and FCF. In the early stage, the formaldehyde emission standard of wood-based panels is E2 (formaldehyde emission ≤30mg/100g), and its formaldehyde emission limit is very loose. Even if it is a product that meets this standard, its formaldehyde content may exceed E1 artificial More than three times the size of the board, seriously endangering human health, so it must not be used for home decoration. Therefore, there was the first environmental protection revolution. In this environmental protection revolution, the floor industry implemented the E1 environmental protection standard, that is, the formaldehyde emission is ≤1.5㎎/L. Although it basically does not pose a threat to the human body, there are still residues in the floor. Many free formaldehyde. The flooring industry has begun the second environmental protection revolution, and introduced the E0 environmental protection standard, which reduced the floor formaldehyde emission to 0.5㎎/L.

4. Look at quality

Good floor should choose good material, good material should be natural, high and moderate density. Some people think that the higher the density of wood-based panels, the better. In fact, it is not. Too high density has a high water swelling rate, which can easily cause dimensional changes and lead to floor deformation. Secondly, it is necessary to rely on advanced flooring production lines and equipment and rigorous technology to produce first-class flooring.

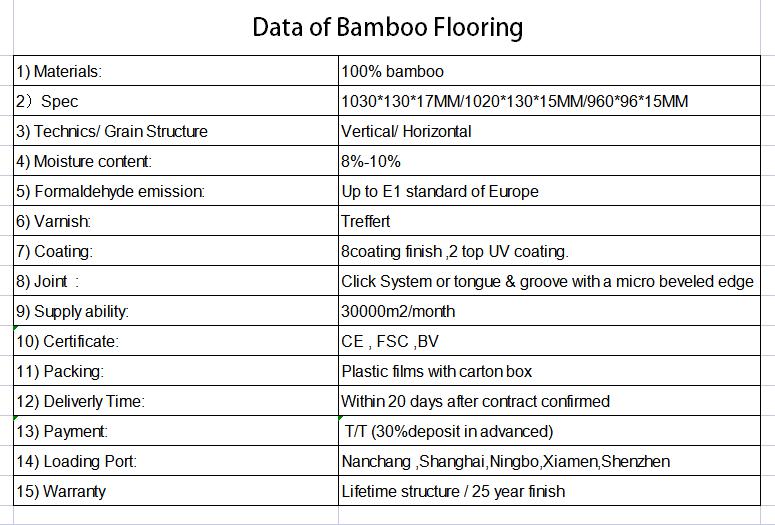

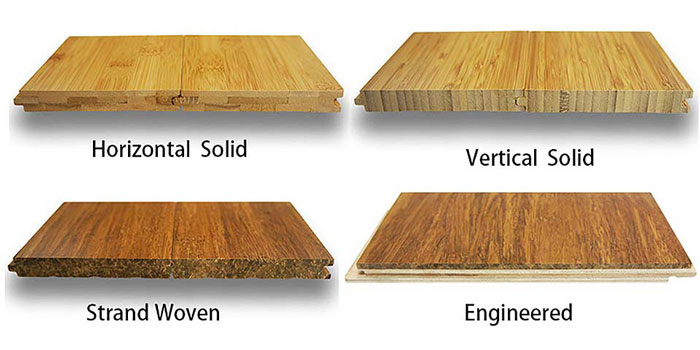

Structure

Detail Images

Bamboo Flooring Advantage

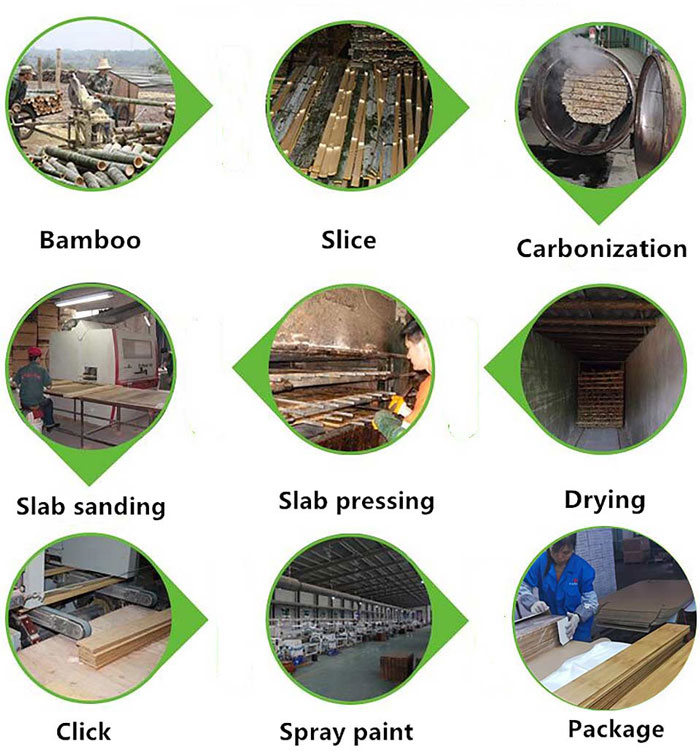

Production Process

Production Line

Packing

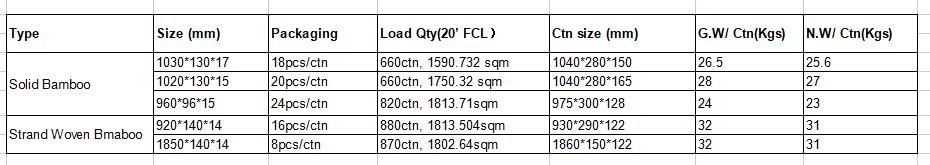

Bamboo Flooring Packing List

Transportation

Application